Packaging Material Knowledge: Summary Of Classification, Common Structures And Production Techniques Of Paper Gift Boxes

To a large extent, carton packaging uses its exquisite shape and decoration to promote and beautify products and improve product competitiveness. In terms of the function and characteristics of the goods, the carton packaging structure should give full play to the molding characteristics of the polyhedron and skillfully use body language to express the characteristics of the goods and the beauty of the packaging. This article shares the classification, common structures and production techniques of paper gift boxes. The content is for advertisers’ reference:

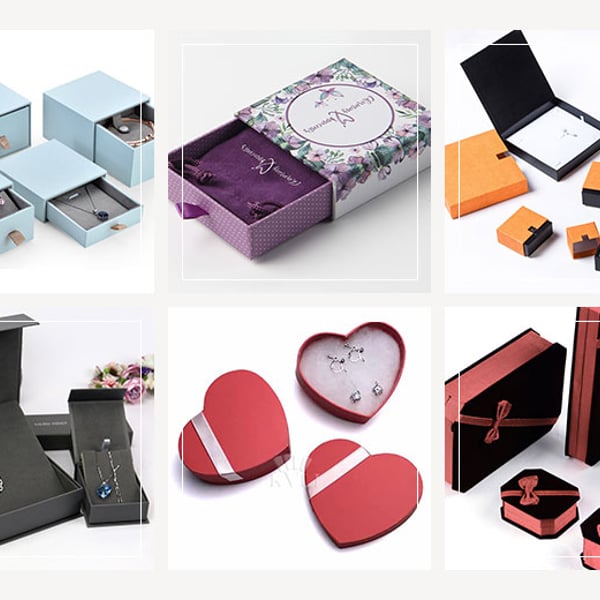

01 Common Classifications Of Gift Boxes

Divided by pasting fabric:

- Paper: including gold and silver cardboard, pearlescent paper and various art papers, etc.

- Leather materials: including genuine leather, simulated leather PU fabrics, etc.

- Fabrics: including various cotton and linen textured fabrics, etc.

Divided by application scope:

- Daily chemicals: mainly used in cosmetics, perfumes, etc.

- Alcohol: Mainly used in white wine, red wine and various foreign wines

- Food: Mainly used in chocolate and health food

- Tobacco: Mainly used in high-end boutique cigarettes

- Digital electronics: mainly used in mobile phones, tablets, etc.

- Jewelry: Mainly used in all kinds of jewelry

02 Common Structures Of Gift Boxes

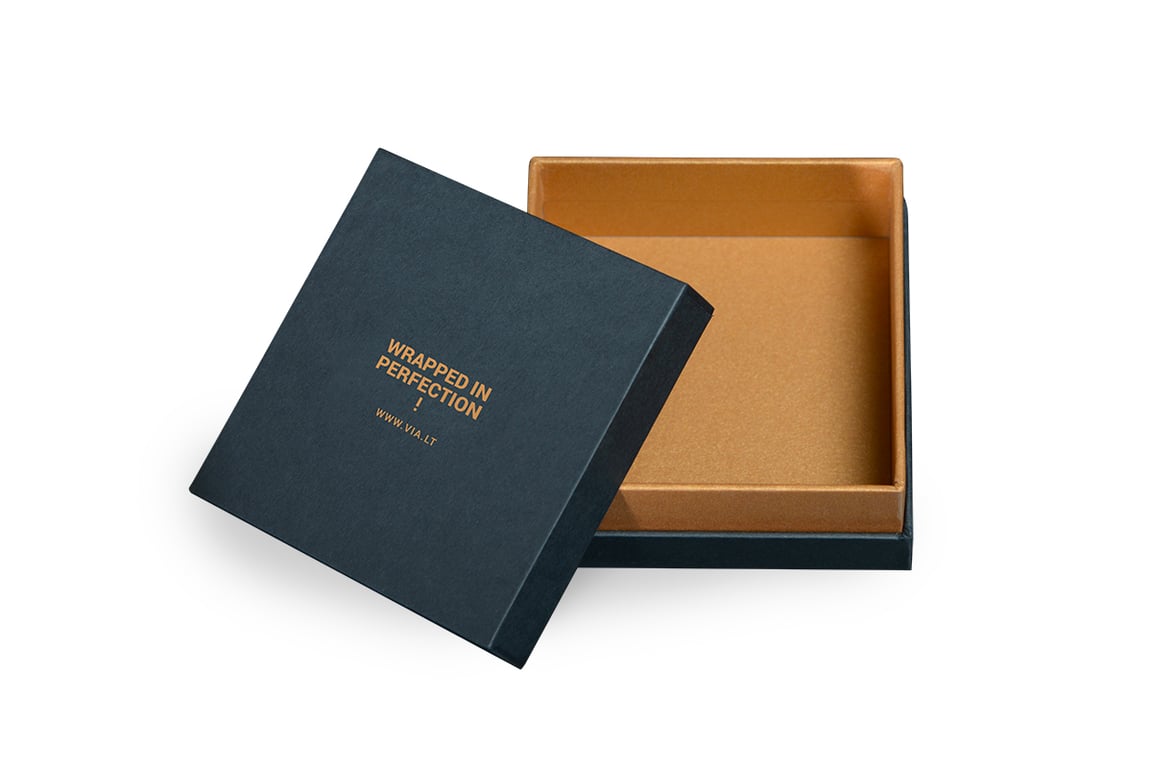

Base and LidBox

It consists of a cover box and a bottom box, which are generally used with a large top and a small bottom.

Book Box

It consists of an outer leather shell and an inner box. The leather shell surrounds the inner box. The bottom of the inner box and the back wall are bonded to the leather shell on both sides. The unbonded upper cover can be opened, and the appearance looks like a hardcover book.

Double Door Box

It consists of a left outer box and a right outer box. There is an inner box on the inside, and the left and right outer boxes are symmetrical.

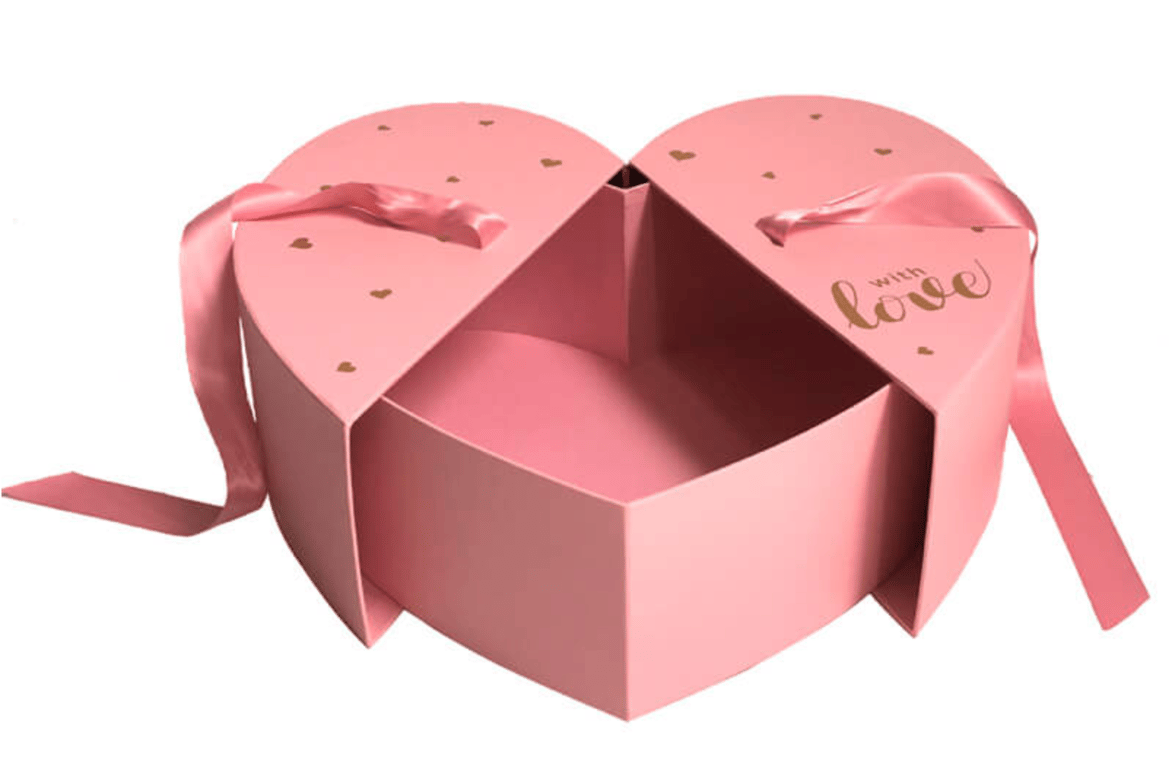

Heart Shaped Box

The box is shaped like a heart, and is mostly a box structure with a base and lid.

Drawer Box

It is a box type with drawer function. When using, pull out the drawer box and it is very convenient to open.

Round Box

The box shape is a perfect circle or ellipse, and most of them have a base and lid box structure.

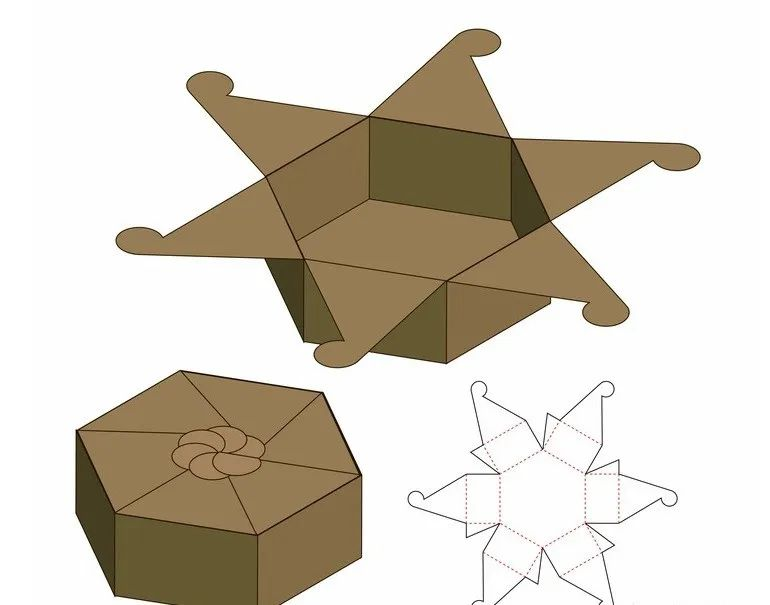

Hexagonal/Octagonal/Polygonal Box

The box shape is six-sided/eight-sided/polygonal, mostly with a base and lid cover structure.

Window Box

Open the required windows on one or more sides of the box, and paste transparent PET and other materials on the inside to fully display the information about the contents.

Folding Box

The gray board is used as the skeleton, and is pasted with coated paper or other paper. Leave a certain distance between the gray board at the bends, and support the whole into a three-dimensional shape when in use. It can be folded freely and does not affect its appearance after forming. After folding, it can save packaging and logistics costs. It is a very practical box type.

Clamshell Box

The back of the box is pasted with tissue paper. It is a combination of the top and bottom cover box and the top and bottom cover box with inserted edges. It can be opened and closed freely from front to back.

Other Special-Shaped Boxes

03 Paper Gift Box Production Process

Paper gift box production process:

Printing → Surface finishing → Outer material die cutting → Gray board die cutting → Gray board slotting → Gray board molding → Outer material pasting → Assembly → Inspection → Packing

Paper selection:

Consider the paper type, such as coated paper, art paper, pearlescent paper, etc.;

Consider the thickness of the paper. Note that the paper should not be too thick, as the paper will easily wrinkle if it is too thick, and it should not be too thin, otherwise the concave and convex effect will not be reflected.

Surface finishing:

Reverse glazing, lamination (glossy film, matte film, touch film, scratch-resistant film, etc.), hot stamping (gold, red gold, colored gold, silver, laser, etc.), local UV, embossing and embossing

Gray board selection

Gray board is produced from a kind of recycled waste paper and is mainly divided into single gray, double gray, full gray and high gloss, depending on the customer's surface smoothness requirements. Gray paper is an environmentally friendly packaging material, and there is no upper limit in special circumstances. Gray boards of appropriate specifications are usually selected according to the specifications of the gift box.

die cutting

Paper gift boxes have high technical requirements for die-cutting. The precision and accuracy of die-cutting directly affects the processing quality of subsequent processes, and will also directly determine the quality of the product.

Grooving

Slotting is a key step in making gift boxes. It involves using a slotting machine to cut out a V-shaped groove on a 1 to 4mm thick gray board. Generally, a connecting layer of about 0.25mm is left. The V-shaped groove is angled, usually 90 degrees. , 120 degrees, you can also choose other angles according to the product structure, but it must be straight outside and square inside after the gray board is bent, with clear edges and corners, and the four corners are accurately aligned.

Paste

According to different product requirements, coated paper, art paper, flannel, leather, etc. are glued or sprayed through a gluing machine, and tightly pasted to the gray board, so that the two become one, thereby making the gray board The appearance is "replaced with a new look".

Note: Generally, packaging boxes are pasted first and then die-cut. Only pasted gift boxes are die-cut first and then pasted. The purpose of this is:

- First, they are afraid of damaging the outer packaging material and affecting the appearance;

- Secondly, the gift box pays attention to the harmony of the overall effect. Only by post-pasting can the support be completely covered, so that the gray of the gray board is wrapped by the innovatively designed outer packaging material, presenting us with a beautiful work of art;

- Third, some boxes with complex structures still require manual pasting, which cannot be replaced by machines.