Commonly Used Printing And Packaging Processes

The printing and packaging industry widely utilizes eight printing techniques: Four-color printing, Spot color printing, Silk-Screen printing, Glossy and Matte PP Lamination, UV Coating, Foil Stamping, and Embossing/Debossing. Ranging from straightforward color blending to intricate customization, these technologies facilitate various printing outcomes. They offer vast potentials for creativity and versatility in the production of an aesthetically diverse range of printed materials.

The following is an introduction to these eight printing technologies.

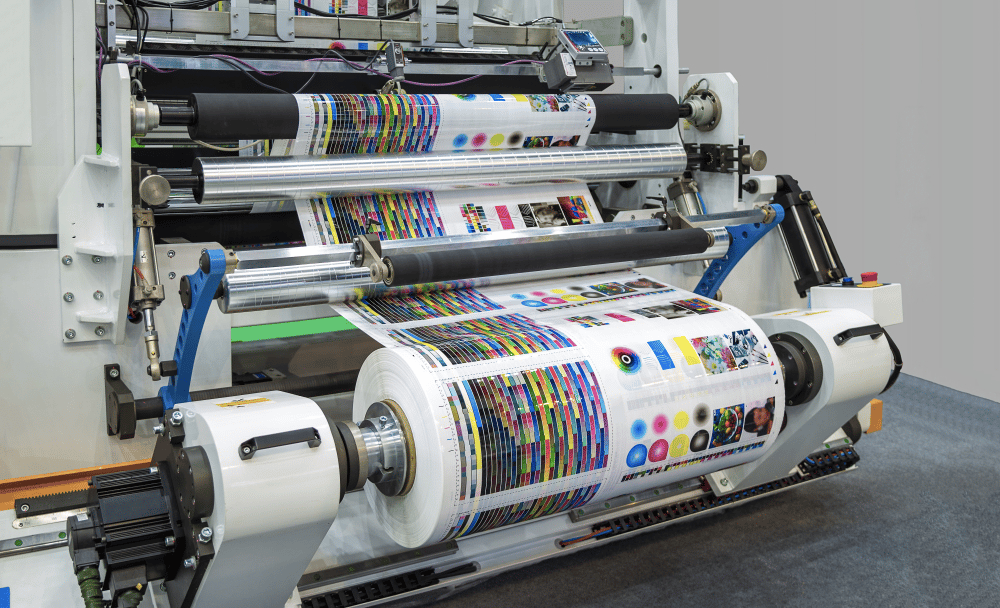

01. Four-Color Printing (4C Process)

- The four colors are: cyan (C), magenta (M), yellow (Y), and black (K) inks. All colors can be mixed by these four inks to ultimately achieve color graphics and text.

- The most common and common type of printing, the effects printed on different substrates are different.

02. Spot Color Printing

- Spot color printing refers to using a special ink to print the color during printing, which is brighter than the color produced by mixing the four colors.

- There are many spot colors. Please refer to the Pantone color card. Gradient printing cannot be achieved with spot colors. If necessary, add four-color printing.

03. Silk-Screen Printing

Screen printing refers to using a silk screen as a plate base and using a photosensitive plate making method to create a screen printing plate with graphics and text. It is the most adaptable and widely used printing method in the world.

Screen printing can not only print on flat surfaces, but also on curved, spherical and concave-convex surfaces.

04. Glossy PP Lamination

- After printing, a transparent plastic film is applied to the surface of the printed matter through hot pressing to protect and increase the gloss. The surface is bright, as shown in the picture below.

- The most basic process of carton surface treatment. Similar to varnish, varnish can enhance the hardness and tensile properties of the paper.

05. Matt PP Lamination

- After printing, a transparent plastic film is applied to the surface of the printed matter through hot pressing to protect and increase the gloss. The surface is matte, as shown in the picture below.

- The most basic process of carton surface treatment is similar to varnishing, but varnishing can enhance the hardness and tensile properties of the paper.

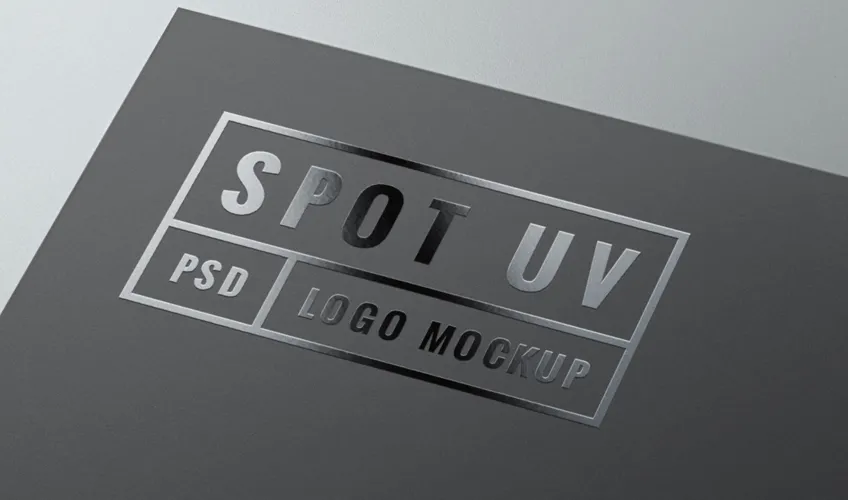

06. UV Coating

- The protruding parts of the printed matter need to be partially glazed and brightened to make the local pattern more three-dimensional.

- When printing with matte glue, there will be no effect when using gloss glue.

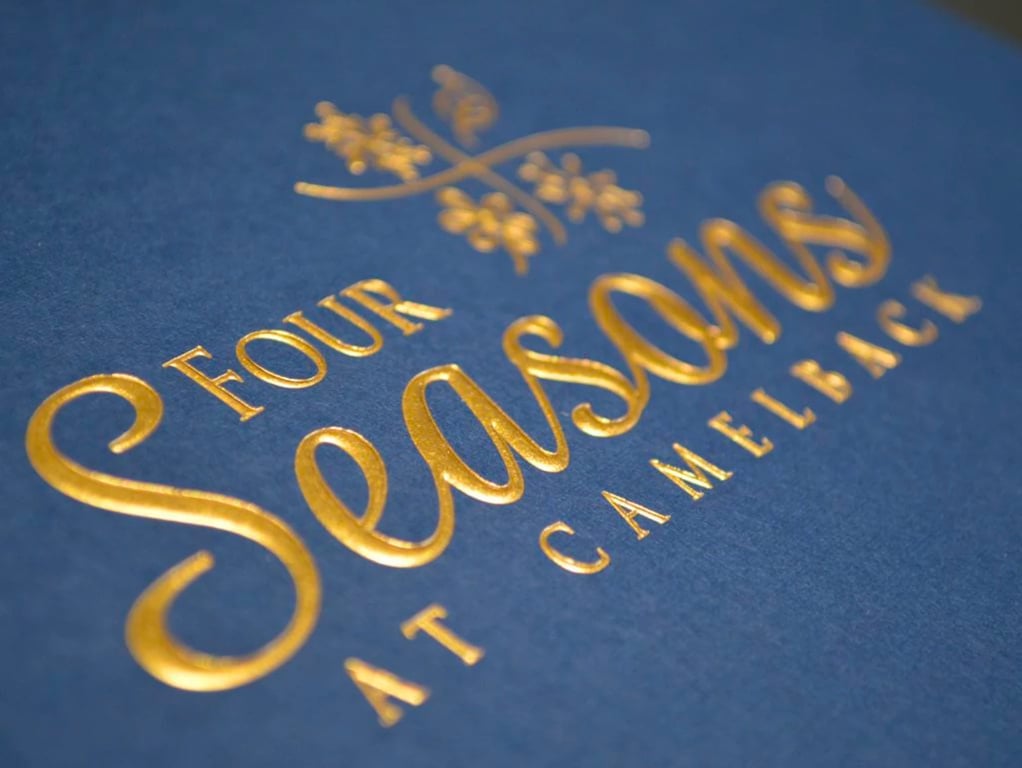

07. Foil Stamp

- Hot stamping uses the principle of hot pressure transfer to transfer the aluminum layer in anodized aluminum to the surface of the substrate to form a special metallic luster effect.

- The printing raw materials include gold, silver, red, green, blue and other colors, but hot stamping can only be single color. There are many kinds of colors, but not all colors are available in the market.

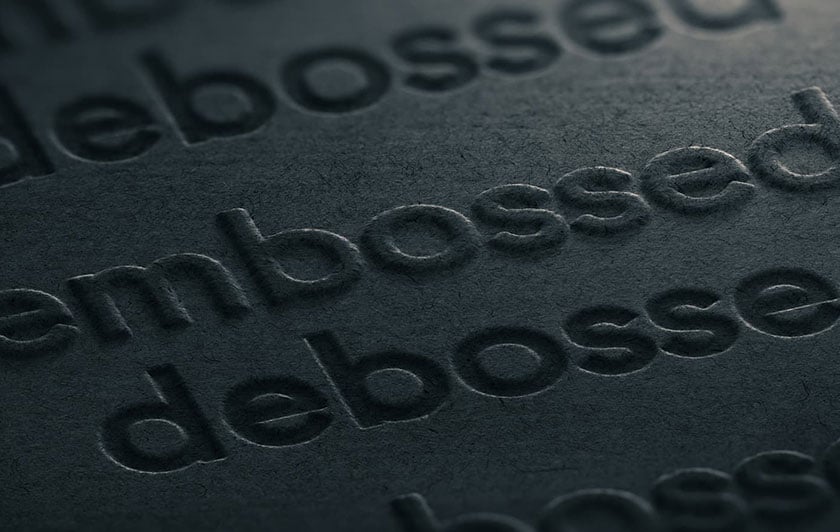

08. Emboss/Deboss

- Use a set of concave and convex templates corresponding to the yin and yang of the graphics and text, place the substrate between them, and press out the relief-like embossed graphics and text by applying greater pressure.

- Paper of various thicknesses is acceptable, but cardboard cannot be embossed.